So what to do when your a homebrewer, a home fermenter, have a green thumb and have an over abundance of tomatoes?

Well after John, the owner of House of Homebrew of Green Bay, suggests on social media .. you decide to make tomato wine!

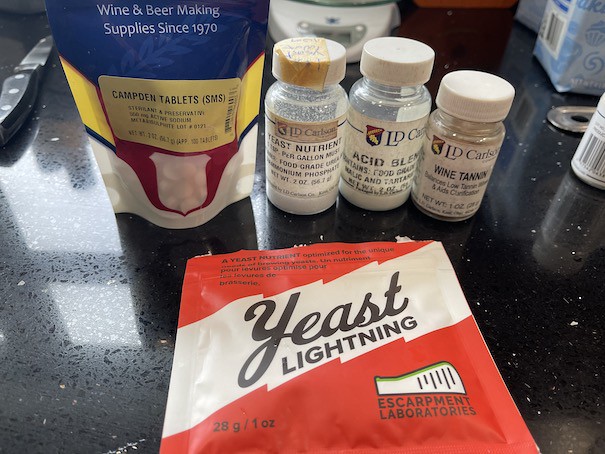

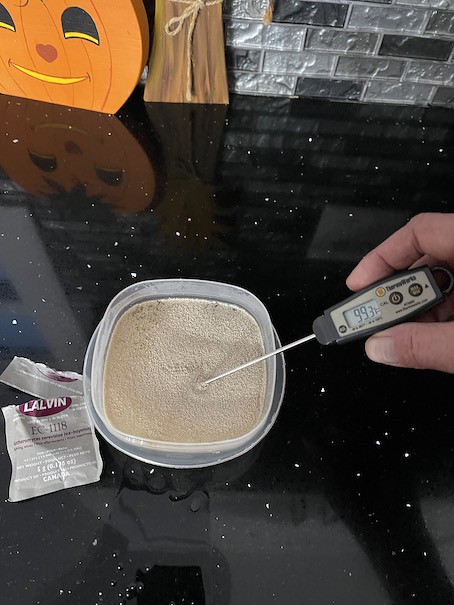

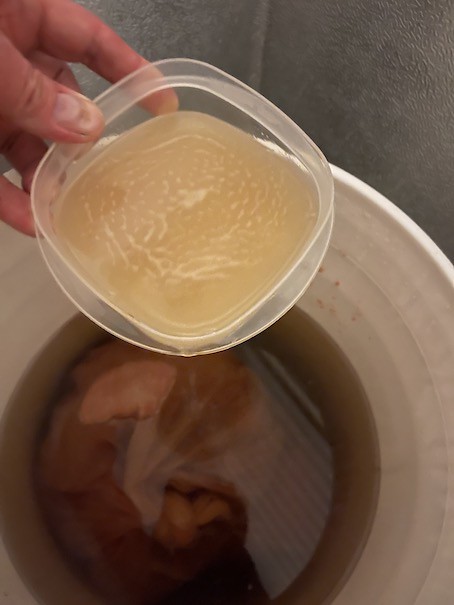

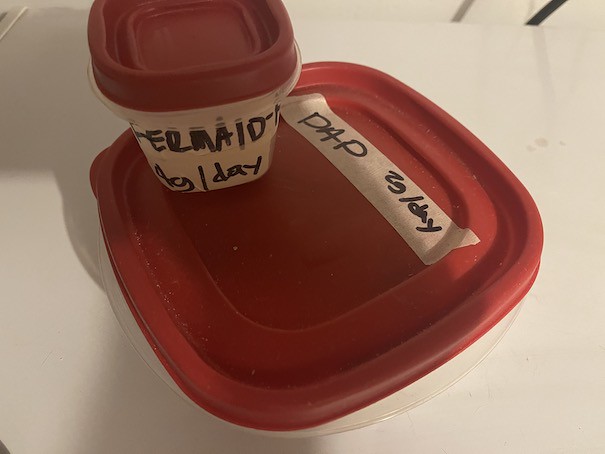

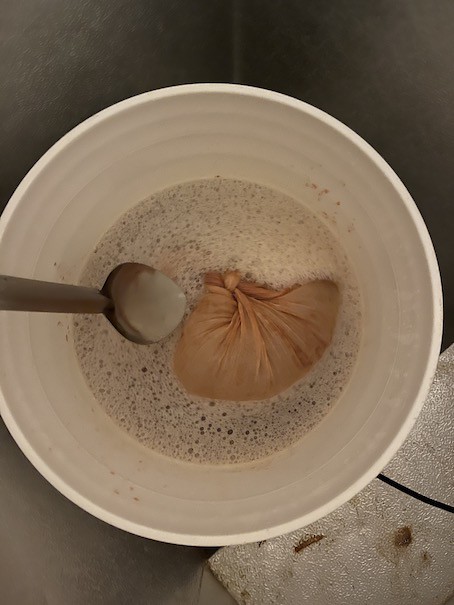

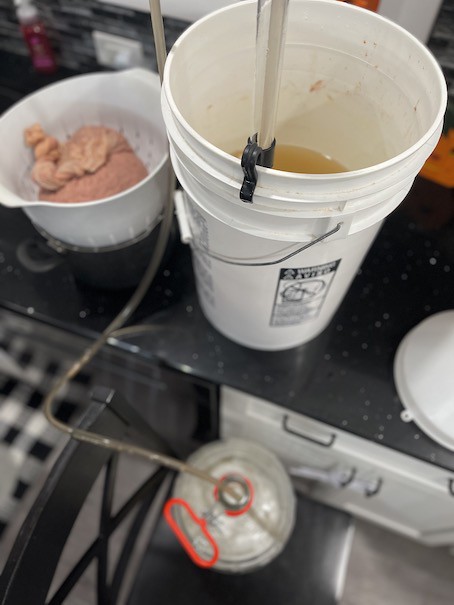

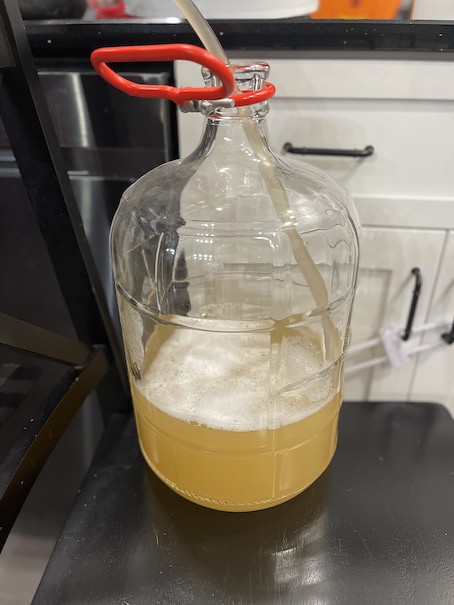

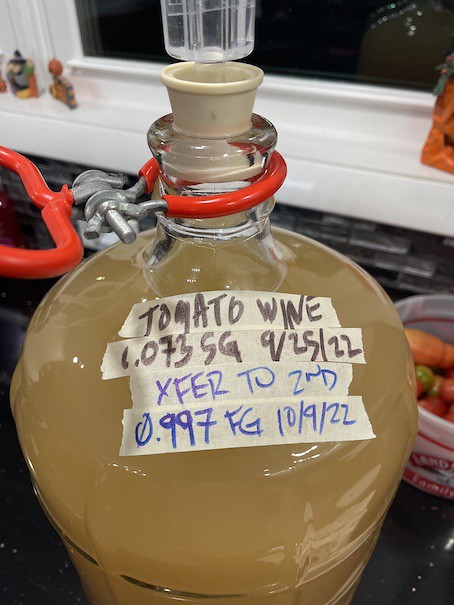

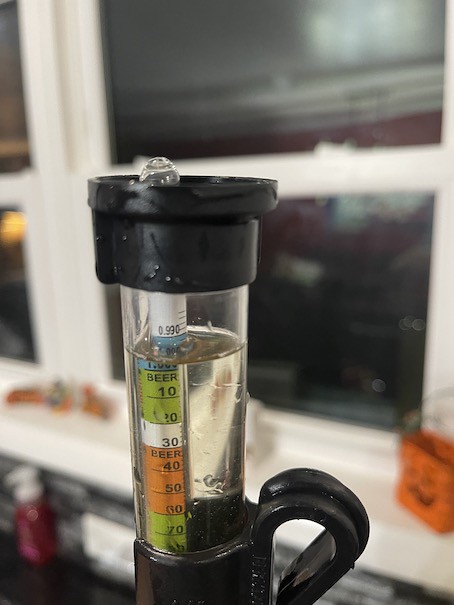

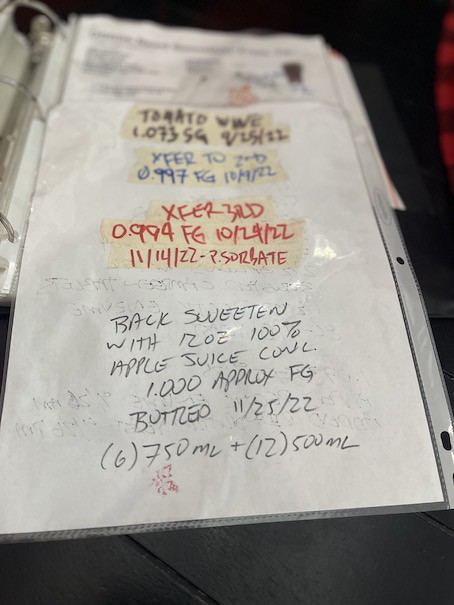

Click here to see the info: Now at first I wasn’t sure if John was just kidding, but I have actually heard of this though. And with some Google searching and some memory recall … I re-found the world of fruit and country wine guru Jack Keller. If you’ve never heard of Jack Keller here is brief intro. Jack’s WineBlog was the first wine blog on the internet. He unfortunately passed away in Sept 2020 but has impact on fruit and country wine lives on. His site doesn’t exist anymore but the Web Archive has it and can be partially accessed here: Link to Archived Winemaking.JackKeller – And someone also Scribd a collection of his recipes and as a PDF download as well Jack did have one book that is still available for purchase on Amazon. Most, if not all, of Jack’s recipes are at 1 gallon batch sizes … so scaling is easy. Do you yourself favor and look him up! He logged numerous wine recipes. Jack’s Keller – Red Tomato Wine – 1 Gallon The only word of caution for red tomato wine is to use only perfectly ripe fruit. They should also be freshly picked. If you have a large crop coming ripe all at once and have already canned enough for the off seasons, then this recipe will be a God-send. It makes one gallon of wine, but multiply it out by however many 4-lb batches of tomatoes you have for the wine. • 4 lbs fresh, ripe red tomatoes Now a brief write up about this recipe: Boil water and dissolve sugar. Meanwhile, wash and cut fruit into chunks, discarding any bruised or insect-scarred parts. Pour fruit and any juice from cutting into nylon straining bag in primary. Tie bag and squash the fruit. Pour the boiling water with dissolved sugar over fruit. Cover and allow to cool one hour, then add acid blend, tannin, yeast nutrient, and crushed Campden tablet. Stir, recover and after 12 hours add pectic enzyme. Wait another 12 hours and add yeast. Stir twice a day for 7 days. Remove nylon bag and allow to drip drain, adding drained juice to primary; do not squeeze bag. Siphon liquid off sediments into secondary, top up, and fit airlock. Rack every 60 days until wine clears, then wait two weeks and rack again. Add stabilizer, wait 10 days, sweeten to taste with sugar water, then bottle. Wine will mature in one year and should be served chilled. Now since I have a lot of tomatoes I decided to go with 3 gallons batch size so I just simpy times all the items listed by 3x – so yes I’m using over 12lbs of tomatoes! You do not use 3x the yeast though, a 11gram sachet is enough for a 6 gallon batch. I also have a press I’ll be using and I’m going to go with a Staggered Nutrient Additions approach with this ferment. Here is a link to how to: Improve you Mead with Staggered Nutrient Additions. Now before you start anything let us talk sanitization. Even though is a “country wine” you need to ensure that everything is cleaned and sanitized. You can’t sanitize anything that isn’t clean … so clean and rinse through and sanitize. I suggest either StarSan or IOStar – Follow mixing and usage instructions – typically it’s 1oz of sanitizer to 5 gallons of water for a concentration of 25 ppm in solution for sanitizer. ANYTHING that touches the fermenter or the must .. I mean anything .. be sure to sanitize it! You’ll thank me later! So start by weigh out 4 lbs of tomatoes. I went over a few ounces over since you will be cutting out any bad or bruised areas – Vary as needed but I processed the tomatoes in the manageable size of the 4lbs at a time. Now cut up the tomatoes into quartered chucks. You don’t have to dice the tomatoes and I will be using a press so “chucks” as shown below should be good. Doesn’t have to be pretty. Now like I said I’ll be using a press so I load 4lbs of tomatoes at a time into the press. If you don’t have a press just bag the tomatoes into a straining bag in primary, tie the bag and squash the fruit in the primary. And squeeze and collect the juice. I then collect the squeezed out tomatoes and place in a straining bag. And place into the primary fermenter (Which I suggest a bucket for primary with the bagged tomatoes and glass for secondary and tertiary fermentations) Now since tomatoes seeds are small and the press allowed the seeds to press though into the juice I decided to use a sanitized wire sieve to collect the seeds. And you see it was a good idea! Now collect and bring you water to a boil to dissolve your sugar. Since we’ll be adding Campden tablets I decided to use my municipal water, otherwise a good idea would be using RO Water. I collected 10-1/2 quarts (2-5/8 gallons) but I reserved back 1.5 quarts incase I didn’t like the SG gravity (which I ended up added back in the volume of water per the recipe) I did also substituted 1lb of sugar for 1lb of honey. Be very careful with boiling your sugar solution – hot and stick bubbling boiling liquid is no joke … so watch what you’re doing! Then pour the sugar solution into the fermenter and over the tomatoes in the strainer bag and cover and let sit for 1 hour. After 1 hour add the crushed Campden tablet(s), yeast nutrient (DAP), acid blend (or malic acid) and wine tannin and mix with a santized spoon to incorporate the additives. Be sure to take a cooled hydrometer sample and record you starting gravity (SG) Now cover and let you must set for 12 hours. And if you have a fermentation chamber that’s a plus, especially for chilling down the hot must. Then 12 hours later add your pectic enzyme. Pectic enzyme breaks down the pectins, which is the “fleshy” part of the fruit. Stir and recover to incorporate the enzymes into the must. And let sit for another 12 hours to allow the enzymes to work. After 12 hours rehydrate your yeast (as manufacturer suggests) – I also added GoFerm to assist the yeast. And pitch your yeast into the must. Now at this point …. this is as far I as I have documented and will be adding to this as the ferment progress along. One day after pitching yeast I gave the must a stir to degas and to punch down the bagged tomatoes back into the must. On odd days I’m stirring and degassing and on even days adding nutrients. So day 2 I’m adding nutrients. Fermentation has slowly started and there are signs of fermentation. But with adding FermAid-K and DAP with a stir it kicks up fermentation for sure! It’s been 2 weeks and it’s time to transfer a secondary fermenter. It’s going from the bucket fermenter into a 3gallon glass carboy. First pulling the bag with the crushed tomatoes. And then placing it into a sanitized colander and collect the dripping into a sanitized pot. Do not totally squeeze the bag … just collect what runs off naturally. While that drains, using an auto siphon that you have sanitized prior, siphon the must into the carboy. Be sure to take a record you gravity – As you can see it has fully fermented below 1.00 to a FG of 0.997 – Very similar to a hard cider ferment finishing dry. Now you can combine the collect drippings from the bag … and below what the spent tomatoes look like. Transfer all the clear must leaving behind the spent yeast and spent trub in the bucket You can transfer and nearly completely to the top of the ferment since there should not be any additional fermentation happening. Now allow the wine to set to settle out in secondary for atleast another 30 days changing on it once a week. I record the steps and reading on masking tape. More updates as it progress …. So check back in from time to time for updates! Time for another transfer! Even though it is SUPER clear already … we can do better yet and even without clarifying additives. Take a reading sample and record the gravity and taste sample! As you can see it has dropped a few more points yet from the transfer to secondary. We’re down to 0.994 … drying out! Be sure to sanitize everything prior to transferring! Leaving behind the spent yeast and the fermentation trub / debris that is settled out. Transferring my notes to the next carboy … Next you need to decide to back sweeten or not. If you want a dry wine … leave it as is and go ahead and bottle. But if you desire to add back some sweetness, without fermentation happening again in the bottle, you HAVE to stabilize the must/wine. If you don’t stabilize prior to back sweetening you will make bottle bombs. To stabilize your wine, cider or mead for back sweetening the process is the same. Add 1/2 teaspoon of Potassium Sorbate (K.Sorbate) per gallon and 1/4 teaspoon of Potassium Metabisulphite (K.Meta) , or (1) crushed campden tablet per gallon. The potassium sorbate (K.Sorbate) prevents new fermentation from happening (Note: potassium sorbate should not be added without potassium metabisulphite – you can end up with off flavors otherwise) The potassium metabisulphite (K.Meta) is a preservative and should kill off any lingering wild yeast cells and protects from bacteria. Now to back sweeten your wine there are varies ways. You can add a 1:1 ratio of water and sugar – (Example: boil 100grams of sugar in 100ml of water is the easiest). Adding fruit juice is another way. Or you can also use Wine Conditioner as well. This tomato wine it’s very “cider’ like so I decided to use 100% apple juice concentrate to back sweeten with. I have used this before in the past. White grape juice concentrate would have also been a good choice as well – but wasn’t available at the store. Then bottle as normal. Making sure to throughly clean and sanitize your bottles. I opt’d for a mixture of 750ml bottles an 500ml bottles (with swing tops) Be sure to note and record all your readings, recipe and notations throughout the process. I hope you enjoy this …. I will attempt to get tasting remarks from club members!

The Winemaking Home Page―the largest home winemaking website in the world and was the first winemaking blog on the internet.

(I’m using a mix of beefsteak, better boy, roma and jetstar)

• 2 lbs granulated sugar

(I used some honey along with sugar)

• 3-1/2 qts water

• 2 tsp acid blend

• 1/2 tsp pectic enzyme

• 1/8 tsp grape tannin

• 1 tsp yeast nutrient

• 1 crushed Campden tablet

• 1 pkg Champagne or Montrachet yeast

(I’m using EC-1118 Yeast)

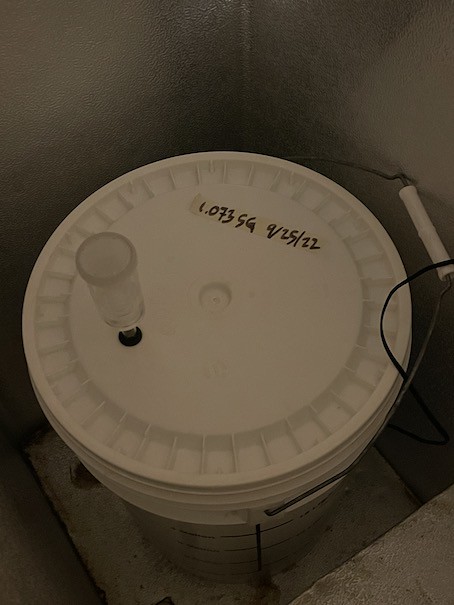

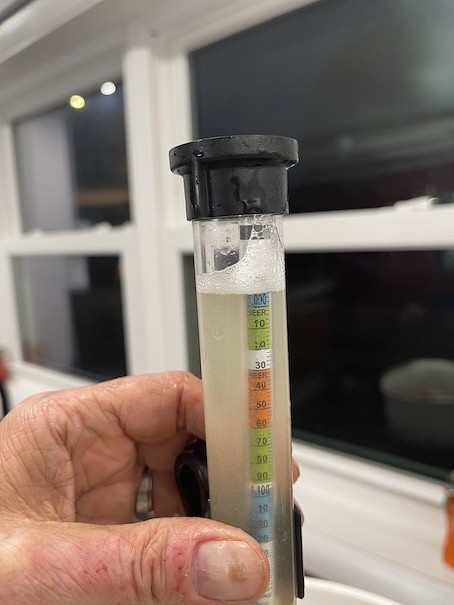

Hard to see from the angle and I had to hold the hydrometer .. but I got a 1.073 / 1.075 SG – You can adjust up or down as you like. I’m fine with the low 1.070s for a starting gravity.Day 2 – Update After Yeast Pitch

2 Week Mark – Transfer to Secondary Fermenter

3 to 4 Week Mark – Transfer to Tertiary Fermenter

5th to 6th Week Mark

Stabilizing, Back Sweetening and BottlingStabilizing

Dissolve the K.Sorbate and K.Meta in some water before adding to the wine. Then give the wine at least (5) days to (1) week for the K.Sorbate and K.Meta to halt the yeast’s ability to ferment sugars anymore. This does not kill off the yeast that still remains, but stops the ability to eat / ferment any sugars.

Documentation is important and makes you be able to repeat and improve in the future.